Airborne Laser Methane Assessment

ALMA is Pergam-Suisse’s aircraft based natural gas leak detection equipment used primarily for reliable and economical integrity inspections of transportation and distribution networks (high and low pressure pipeline, wells and gathering lines, compressor stations, metering stations, etc..). ALMA can also be used for detection and mapping of other sources of methane such as landfills and farming.ALMA operation principle

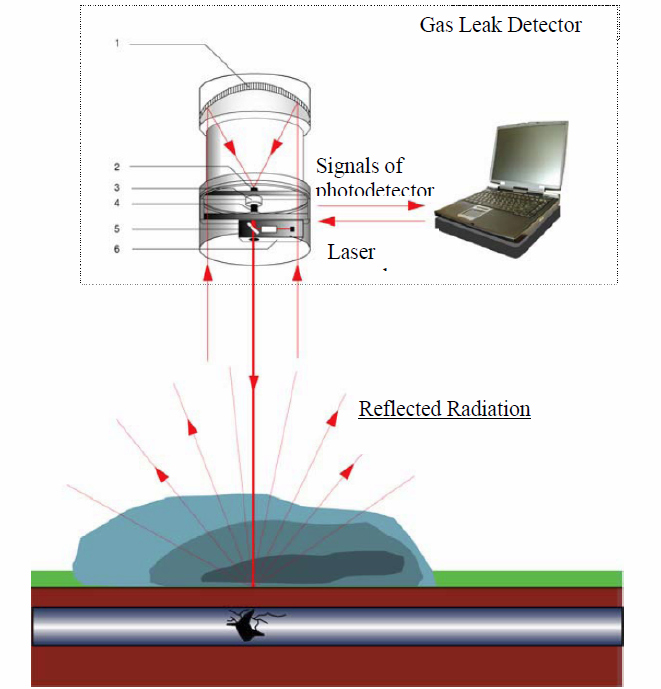

The ALMA G2 (second generation) is an improved version of the equipment to reliably detect elevated methane concentrations to ground level at distances up to 150m (500feet). The equipment is based on an infrared Laser with output radiation wavelength in vicinity of 1650 nm of which methane absorbs. A Laser beam is emitted from the Optical Unit (OU) and hits a topographic object (soil, grass, trees, concrete, asphalt, etc.). The system analyzes the Laser light back scatter to determine how much if any of the Laser energy was absorbed by the methane in natural gas. A unique detection algorithm allows for real-time measurement of total methane content along the Laser light path from the OU to the topographic object. The OU also contains a laser rangefinder for atmospheric methane compensation and up to 3 cameras to document laser beam location and rightof- way.

1 – Receiving mirror, 2 – Photodetector, 3 – Laser,

4 – Objective, 5 – Beam splitter, 6 – Reference channel

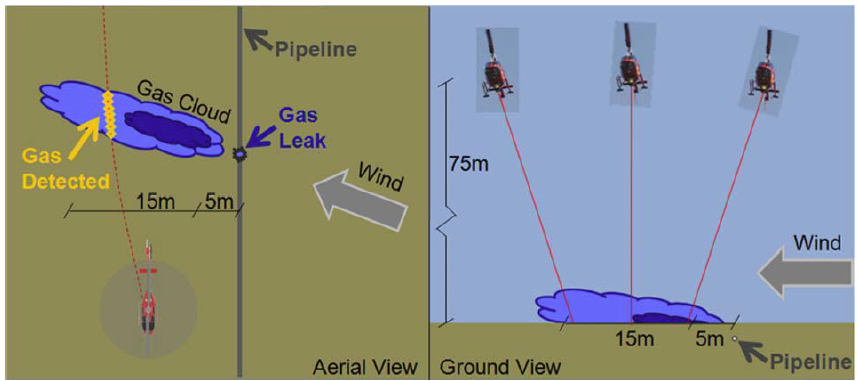

The methane leak detection reliability is dependent on aiming the laser beam downwind of the pipeline to intercept the gas cloud. Optimal operation is between 5 and 20 meters downwind. The optical unit is rigidly fixed to the helicopter enabling the pilot to control the laser beam location with the helicopter position and attitude (roll, pitch, and yaw angles). The pilot monitor which displays either the video from the camera aligned with the laser or GPS based moving map aid the pilot in aiming the Laser. It is advisable that pilot practice aiming the Laser before starting the inspection (example: follow a road).

The operator monitors the data provided by the system to confirm leak detections, helps the pilot with navigating along the pipeline, and determine if an area needs further inspection. The system continually records the data including GPS information, video images, etc… A postinspection report is generated via data analysis software.

The inspection data which includes all measurement values and GPS coordinate is saved once initiated by the operator. The entire inspection can be analyzed post flight. The equipment converts and averages via a proprietary algorithm the results of several hundred laser pulse scans into 0.2 and 0.04 sec sample data streams recorded simultaneously to ensure the reliability of the detection. The data streams are displayed in parallel on the user interface in real-time.

The gas concentration data is in ppm*m (part per million * meter) as the laser measures along the entire path of the laser beam. When the gas concentration measured exceeds the alarm limit audible and visual indictors activate, and the data about the detection location (registration time, GPS coordinates, concentration, etc.) are displayed on the screen and recorded into a dedicated file. The location color coded by size is also depicted on a trajectory graph. Synchronize video is recorded for the up to 3x cameras providing images for any location during the flight.

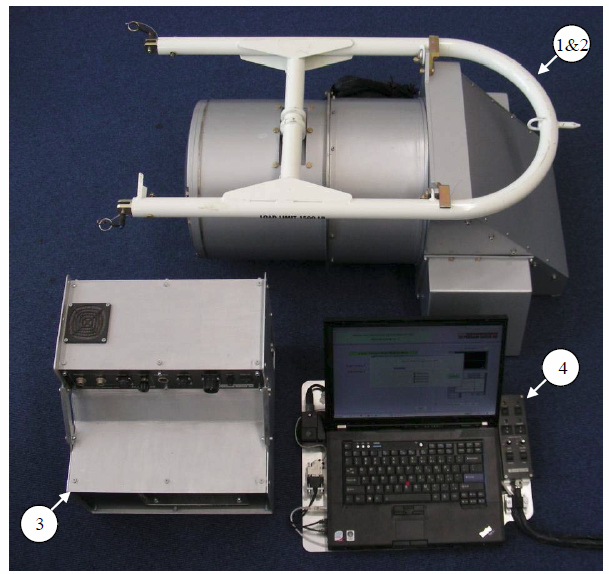

ALMA G2 COMPONENTS

- 1. Optical unit, including

- 1.1. Laser, optics, photodetectors, mirrors;

- 1.2. Up to 3 video cameras;

- 1.3. Rangefinder;

- 1.4. Set of electrical cables.

- 2. Mount frame for Optical unit.

- 3. Electronic unit (D-box), including

- 3.1. Digital video recorder (DVR).

- 4. Laptop with control panel, including set of cables.

- 5. GPS receiver with cable.

- 6. Pilot monitor.

- 7. On-line control software.

- 8. Off-line data process software

- 9. Accessories:

- 9.1. AC 220V adapters for laptop,

- 9.2. AC 220V power supply unit;

- 9.3. Transportation cases;

- 9.4. Installation Tool kit;

- 10. Operating Manuals.

- 11. CD with copies of software.

Pergam Laser Gas Leak Detector on Helicopter

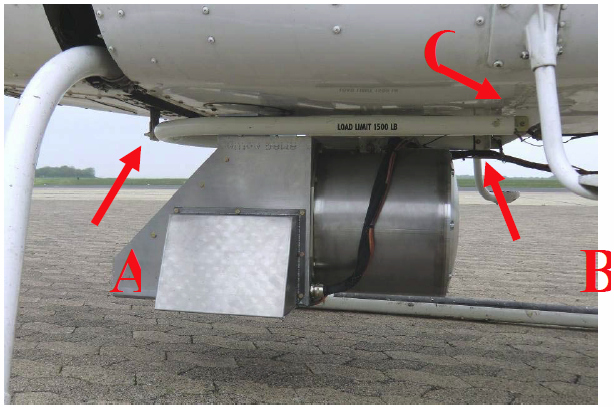

ALMA G2 gas leak detector is a compact system and can be installed, tested, and ready for operation in as little as 1 hour. ALMA G2’s standard configuration is for mounting on the Bell or Augusta JetRanger, but can be customized for installation on other types of helicopters. The installation can be performed by operator and pilot except for the first install of the monitor mount which requires holes to be drilled in the console sun cover.Steps for JetRanger install

- The ALMA G2 Optical Unit (OU) is mounted on a standard cargo hook frame which attaches to the hardpoints on the helicopter’s belly.

- The ALMA D-Box is secured to rear left seat by the seat belt.

- The OU cables are secured to the helicopter passing through the rear left door window and connected to the D-Box.

- The monitor mount, monitor, and GPS are installed with the cable secured to the helicopter then connected to the D-Box.

- The power cable is connected to the helicopter aux power connector then secured to the helicopter and connected to the D-Box

- The operator laptop plate is position then cables secured to helicopter and connected to DBox.

Technical specification

ALMA is designed for work under the following conditions:

- a) the temperature of environmental air is from -100С to +400С;

- b) the relative humidity of environmental air is up to 99% (at the temperature of +250С);

- c) atmospheric pressure is from 0.08 to 0.107 МPа;

- d) external shock loadings on the optical unit during measurements are no more than 1g;

- e) external shock loadings on the optical unit during transportation are no more than 3g.

Basic operational and metrological characteristics of ALMA are following.

- The weight of the optical unit is 52 kg/114lbs (with the attached bundle of cables).

- The overall dimensions of the optical unit: 950 x 700 x 450 mm.

- The weight of the electronic unit is 22 kg/44lbs.

- The dimensions of the electronic unit are 400 x 400 x 360 mm.

- The length of the electric communication line between the optical unit and the electronic case is at least 3 m.

- The length of the DC source power cable is at least 2 m.

- The length of the GPS cable is 5 m.

- The length of the monitor cable is 2 m.

- Start-up time of the device after turning on is 10 minutes.

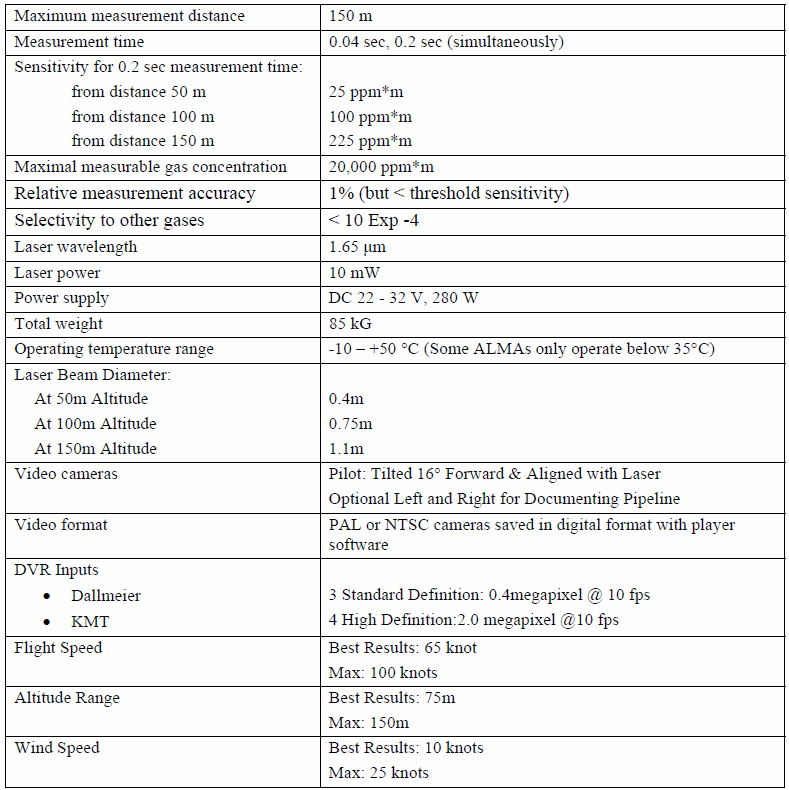

ALMA G2 Technical Parameters

Notes:

(1) Threshold sensitivity of gas concentration measurements Co depends on the distance between the device and a target, as well аs on the target reflection factor at the operation wavelength. The values of threshold sensitivity Co for standard topographic targets (soil, grass, trees, bush, sand, concrete) with mean value = 0.25 are given in the table.

(2) ppm*m (part per million * meter) – product of quota of gas molecules per million air molecules and optical path length.

OPERATION LIMITATIONS AND SAFETY RULES

General Laser Safety Information- Laser equipment is classified to represent the health hazard. The higher the classification number the more dangerous the laser is to your eyes. The classification number depends on many things including the power of the laser and distance from the source.

— Class 2 is considered safe is the exposure time is very short, but Pergam- Suisse recommends to avoid looking or staring into the laser beam path.

- The ALMA G2 has 2x invisible and 1x visible laser sources:

— A Class 1 laser in the Rangefinder to measure the distance to the ground. The laser beam is invisible and enters open air when it passes the lenses (green oval in picture below).

— Rangefinder Red Aiming Laser is Class 2 visible (red arrow in picture) and MUST BE OFF

- Operation Ambient Temperature: -10 to +40 0C. If stored below 00C, equipment must be warmed before operation.

- Use of ALMA laptop is only for operations of the equipment, and data and video processing. Changing operating system or software parameters, installing other software, and connecting to unprotected internet can impact or disrupt equipment operation and reliability.

- Only Pergam-Suisse certified operators can install and operate equipment.

- Shock loads to the equipment may not exceed 1g during operation, installation, or transport.

- Instructions must be followed for installation, start-up, operation, shutdown, removal, and packing to avoid damage to system or its reliability. The equipment must be de-energized before any cables are removed.

- The equipment must be turned off and removed from power source when not in use.