Methane (CH4) emissions

Methane emissions from natural gas production are down 14 percent since 1990, while natural gas output increased more than 50 percent over the same period. Moreover, increased use of natural gas is the main reason U.S. carbon dioxide emissions are at 25-year lows, providing Americans with the cleanest air in years.It starts with advanced data analytics that increasingly guide industry operations, from exploration and development to refining. Operators can crunch data to determine the safest, most productive ways to develop, transport and process natural gas and oil.

World Gas Conference and Exhibition (WGC)

WGC exhibitor Eni’s supercomputer is one example of the technology natural gas and oil companies are increasingly using to process data to create more accurate reservoir models, allowing them to target wells more precisely, increase efficiency, decrease emissions and produce cost savings. Their HPC4 — “the most powerful industrial computer in the world” — is set to allow more refined exploration techniques using next-generation analytics. From the company’s website:“Thanks to HPC4 in May 2018 Eni has achieved breakthrough in Oil & Gas reservoir numerical modeling: it executed 100,000 high-resolution reservoir model simulation runs, taking into account geological uncertainties, in a record time of 15 hours. In comparison, most reservoir engineers in the industry can run just one single simulation run in a few hours with CPU-based hardware and software.”

Eni chief executive officer, Claudio Descalzi:

“These technologies will enable us… to accelerate and make the entire upstream process more efficient and accurate, reducing risks in the exploration phase and … increase the level of reliability, technical integrity and operability of all our productive plants, while minimizing operational risks, with benefits both in terms of safety and environmental impact. [These] have been engineered to ensure the maximum level of energy efficiency in order to minimize CO2 emissions and operating costs.”

Industry’s focus on reducing emissions was clear throughout last week’s conference – as well as the technological breakthroughs that are helping to achieve those reductions.

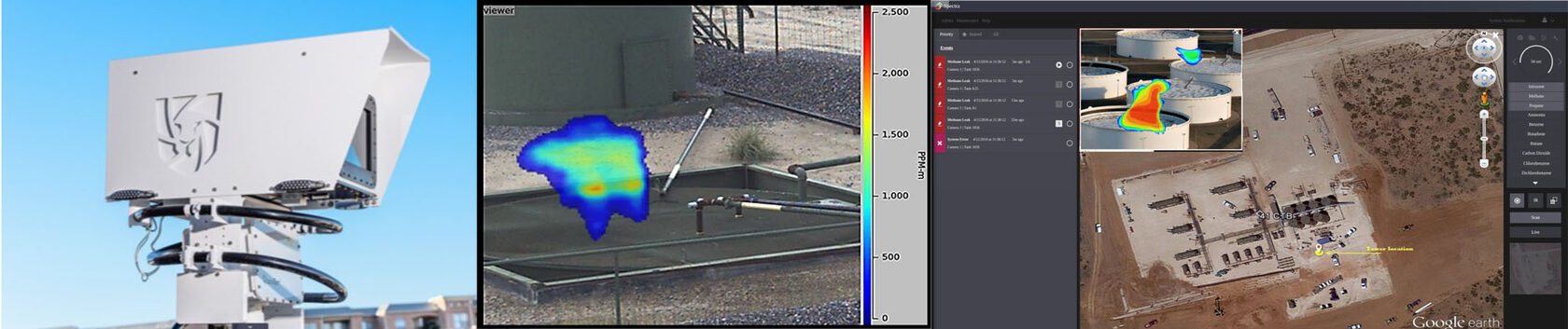

Also on display, Houston-based Rebellion Photonics has developed what they call the Gas Cloud Imaging (GCI) camera, a hyperspectral imaging camera that monitors, quantifies and displays gas leaks in real time as far as 2 miles away. For confined areas, they provide mini GCI cameras that can detect leaks as far away as 110 yards. Last week, this technology earned them the World Gas Conference 2018 Innovation Award for emissions detection and mitigation.

The Gas Cloud Imaging (GCI) cameras are video cameras that monitor, quantify, and display explosive, harmful gas leaks as they occur. With just a few cameras, a large area can be monitored day and night. Our GCI systems can instantly detect what gases are leaking and how much is leaking. This allows the user to assess the situation, preventing exposure to a potentially lethal environment.

The GCI camera uses infrared absorption spectroscopy and can determine what gases are present by analyzing absorption signatures. The camera operates in the long-wave spectral regions, which allows it in real time to differentiate and quantify gases and liquids that are present. According to the company, its self-calibrating hardware is 100 times more accurate in leak detection than conventional hardware and can estimate the volume of emissions within 10 percent accuracy.

Ultimately, the company’s technology hopes to allow operators to identify and prioritize their work around the clock, reducing time spent investigating false alarms created by steam or heat.

Also seen on the WGC show floor was Pergam-Suisse and its soon-to-be-released Laser Falcon, another emissions-detection technology that’s light enough to mount on drones and other small robotics, increasing accessibility to difficult or remote operations while helping to protect workers.

The Laser Falcon is a laser-type methane gas detector that uses the same measuring technology as the company’s LaserMethane mini, but it’s much lighter – approximately 8 ounces vs. 1.3 pounds – so it can used with a variety of applications, including airborne methane monitoring and robotic instrumentation. According to their spec-sheets, measurement data is sent through a communication port and is backed up in a Micro SD card, with power supplied through external connector enabling continuous operation.

This list wouldn’t be complete without an example of industry innovation based on the “internet of things."

Emerson recently announced a new Plantweb Insight application for wireless pressure gauges that displays data in an easy-to-understand dashboard for maintenance leads and instrumentation and electrical personnel. Its suite of applications collectively helps users quickly make sense of plant data and drive overall enterprise profitability. From their announcement:

This Industrial Internet of Things (IIoT) application delivers field data from a fleet of wireless pressure gauges as frequently as once per minute. By keeping operators updated on changing conditions remotely, the app allows personnel to make fewer manual rounds and minimize their exposure to hazardous areas.

The new application adds to what they call their “digital ecosystem” that takes advantage of “IIoT innovations to extend the benefits of automation beyond process control to the entire enterprise”, providing maintenance and operations personnel with actionable, up-to-date process information in any location, improving reliability, safety, production, and energy management.

Again, these are just a few of the many ways industry is using technology to be more efficient, more productive and cleaner – for the air and environment.

Industry also has diagnostic tools that travel inside pipelines, scanning the walls for even the smallest of cracks using technologies similar to an ultrasound or MRI. They’re part of the reason operators often can prevent incidents before they occur, contributing to a safety record that saw 99.999 percent of crude oil and petroleum products delivered by pipeline reach their destination safely.

Meanwhile, new technologies help capture carbon dioxide from power plants, reducing CO2 emissions and potentially making natural gas-fueled electricity generation even cleaner.

On-site cogeneration technology captures heat generated from the production of electricity and uses it for production, refining and chemical processing operations, reducing facility energy consumption and helping improve air quality.

Fuel cells provide critical energy backup for many large facilities, and they can provide primary energy for remote locations. Fuel cell technology generates electricity from hydrogen while emitting nothing but water.

Of course, natural gas and oil companies are dedicated to innovations in technology, reducing emissions and continuing that progress in the future. It’s good for business.

But it’s more than a business priority. It’s right for the environment and improving air quality – and that’s everyone’s business.