The natural gas has always played a central role in the national energy system, but for its supply Italy is strongly dependent on abroad, considering that 90% of consumption is covered by imports. Therefore, a crucial role within the gas system is played by the storage facilities, sites where the gas is re-injected into depleted fields, taking it from the transport network, and then being put back into operation according to market demands. In this way, the storage facilities provide a fundamental contribution to the country's energy security, on the one hand by responding in real time to market gas requests, and on the other by ensuring the maintenance of "strategic" reserves to be used to cope with exceptional situations of climatic or political type. It goes without saying that due to the high volumes of gas stored and the treatments that the resource undergoes to be supplied and introduced into the network or stored in the reservoir, these sites must be managed according to the highest safety standards.

And according to the highest safety standards, Edison Stoccaggio, a company of the Edison Group and the second largest Italian company in the sector in terms of number of plants and quantity of stored natural gas, has always operated. The company provides its services through three storage sites: the "Collalto Storage" field, in the province of Treviso, the "Cellino Storage" field, in the province of Teramo, and the "San Potito e Cotignola Storage" field, in Ravenna province. Plants all equipped with advanced management and control systems that allow to monitor at any time operation, ensuring maximum safety of people, environment and equipment. And when it comes to gas, safety is a priority. And just to further increase the already high levels of security of its infrastructures the company has equipped itself with an innovative solution for remote gas detection based on laser diode technology. It deals with of LMS detectors (Laser Monitoring System), laser systems capable of detecting molecules of methane up to 50 m distance in the version LMS-mini, the one adopted by the company, e 150 meters in the standard version.

Developed and produced by Pergam Italia, a Brescia-based company specialized in manufacturing and distribution of diagnostic and engineering equipment for the most diverse industrial sectors, these Fixed laser systems were designed for the constant monitoring of sensitive areas, such as compressor stations, gas tanks, storage areas , distribution centers and terminals Lng (Liquified natural gas); Systems that Edison Storage, first in Europe, has installed in the "Collalto Storage" Field which, with a storage capacity of approx 600 million cubic meters of natural gas, is the its largest site. The systems allow you to monitor the 6 clusters, i.e. the well areas ach of which is made up of several wells in which the gas serving the storage center is stored.

Increasingly higher safety standards

“Always open to the challenges of innovation, we have this solution for the characteristics that characterize it, such as high sensitivity and precision in detecting the presence of gas, combined with the ability to monitor very large areas. Characteristics linked to the completely new technology for the sector on which it is based” explains Antonio Crisante, storage operations manager at Edison Stoccaggio. “In short, a solution that seemed to us optimal for integrating and completing the complex of our plant control systems and raising the level of safety and quality even higher”.

How it is done

The technology behind the LMS systems is highly innovative: it uses a diode that generates a laser with a particular spectral length, sensitive exclusively to methane, which allows the system to detect the presence of the gas remotely in real time and without generating false alarms.

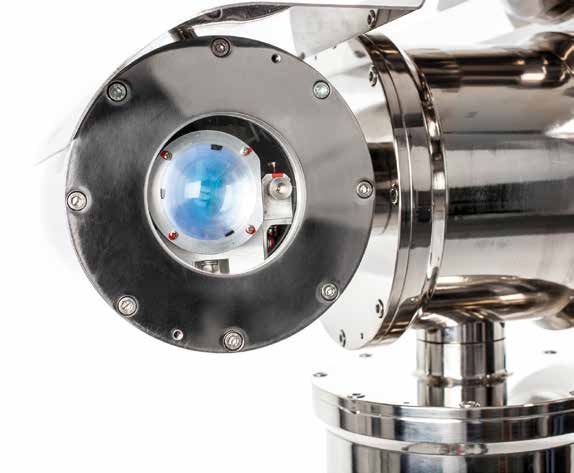

The optical unit is installed inside a swiveled platform, which scans the critical points following a pre-set path, with a range of motion up to 360 ° on the Azimuth axis and ranging from -90 ° to + 30 ° on the vertical axis. In this way, a single instrument can control a large surface area, which reaches over 70,000 square meters in the case of the LMS version, constantly scanning the system in total automation and ensuring its monitoring 24 hours a day, 7 days a week. The LMS and mini systems are also equipped with a double alarm (acoustic and visual), present in the control room of the control unit, which in the event of a gas leak, alerts the staff on duty with an audible signal and a visual warning on the monitor.

In addition, with extremely fast response times, in order to intervene immediately in the event of a report. In fact, laser technology ensures a detection speed of 0.1 seconds, incomparable with respect to the times of the traditional solutions, which must come into contact with the gas cloud to detect its presence, and which are measured in seconds or minutes depending on the strength and direction of the wind.

A system that self-calibrates

Fewer devices in the field also means lower management and maintenance costs. In fact, the new systems do not need any particular maintenance, because, unlike traditional technologies that require calibration every three or six months, they self-calibrate during use. This is thanks to a reference cell they are equipped with, containing a small amount of methane, which is used by the system as a reference parameter to perform the concentration and calibration control. "In addition, each device is equipped with a digital camera, which allows operators in the control room to view the plant at any time" explains Mario D'Alessandro, Head of the Environmental Protection and Safety and Integrated Management System of Edison Storage."A very useful plus, particularly in the event of a methane presence signal, but also in the event of an intrusion or other signal, and which satisfies our other need to also have a visual control of the clusters, which are located at different distances from the control center".

A double level of alert

The data collected by the sensors are sent, via optical fiber, in real time to the PC-servers located inside the Edison Storage control room (one for each LMS), on which the software, also developed by Pergam, is installed for systems management (with different access and functionality for the plant manager). The PC-servers were then interfaced with the DCS (Distributed Control System), so that all information is displayed by the operator and, in the event of an alarm, the safety procedure is automatically activated. All the data relating to the inspected areas and any identified dispersions are also saved in the PC-servers, with the methane concentrations detected, in order to have a history and process an analysis with consequent report, thanks to the software.Another strong point of the system is the ability to calibrate the alert with a very high sensitivity. "The system has been calibrated on two different alarm levels" explains D’Alessandro.

"A pre-alarm, which is triggered in the event of detection of almost infinitesimal methane concentrations, in order to allow us to identify every slightest sign of a possible anomaly and intervene promptly to resolve it, and the real alarm, which is triggered after detection of a concentration that is always very low, automatically activating the maneuvers to make the well safe, with the closure of the valves and the blocking of the activity".

The project - Gas Leak Detector

The installation of the LMS-mini systems on the 6 clusters of the Collalto site was started in the summer of last year and ended in mid-autumn."A device has been installed in each cluster that ensures continuous monitoring of the wellheads present and of the surface plants at their service" continues D'Alessandro. "Once the optimal placement point of the instruments had been chosen, it was only necessary to mount the poles, 4 m high, to house them and bring the power supply cable to their base, without the need to lay a cable for the transmission of the data, as Edison Stoccaggio, a pioneer also in this respect, had for years connected all the wells and the power station with optical fiber”. Internal tests were carried out between October and November, and in January those with the Fire Brigade of the Treviso Command, Arpa Veneto and Unmig (National Mining Office for Hydrocarbons and Georesources), and then the system was put into operation.

"We are very satisfied with the entire project and with this new technology, which stands out for its extreme sensitivity in detecting every trace of methane. Sensitivity that has been confirmed in all the tests we have performed and which is combined with an equally extreme reliability ”concludes Crisante. "The system, thanks to the high selectivity of laser technology, in these months of operation has never generated false alarms, which constitute an inconvenience to be taken into account when using very sensitive and sophisticated instruments, which could therefore have malfunctions that cause incorrect reports. But obviously we are satisfied above all because such a sensitive and calibrated system for detecting truly infinitesimal traces of gas has not detected even the slightest leak from our plants, confirming the high quality and safety levels that characterize the work of Edison Storage and which now, even with this new system, is further elevated”.

Source: "Servizi a rete" Magazine, July-August 2021 release.